Check Out Different Sorts Of Membrane Switch Technologies for Your Needs

Exploring the Advantages of Membrane Switches Over in Modern Electronic Tools

The combination of membrane switches over into contemporary digital equipment presents several engaging advantages that warrant factor to consider. The cost-effectiveness of membrane layer changes settings them as a feasible option for suppliers looking for to maximize their item offerings.

Style Adaptability

Style adaptability is a crucial advantage of membrane switches, enabling producers to develop personalized user interfaces that satisfy certain operational requirements. This flexibility is necessary in an era where user experience and performance are paramount. Membrane layer switches can be designed in numerous forms, sizes, and colors, enabling aesthetic integration into diverse electronic gadgets.

The printed graphics can be customized to match branding, while the responsive responses can be readjusted to enhance user communication. Additionally, membrane switches can integrate multiple layers, allowing attributes such as backlighting and protective overlays, which add to both aesthetic appeal and performance.

Manufacturers can likewise use various products, such as polyester or polycarbonate, to align with particular application requirements. This versatility prolongs to the configuration of the button layout, permitting the assimilation of numerous functions within a solitary interface.

The capability to customize not just boosts the use of electronic tools however additionally allows for the consolidation of sophisticated innovations, such as capacitive touch. As an outcome, membrane layer buttons are an optimal selection for a large array of applications, ranging from medical tools to customer electronic devices, making certain that customer demands are continually fulfilled.

Resilience and Longevity

Longevity and longevity are crucial variables that boost the charm of membrane switches in modern electronic tools. These switches are designed to stand up to difficult atmospheres, including exposure to moisture, dust, and numerous chemicals. The robust products utilized in their building, such as polyester and polycarbonate, add substantially to their resistance versus abrasion and influence, making certain that they maintain functionality even under difficult conditions.

In addition, membrane buttons are inherently secured, preventing impurities from infiltrating the interior elements. This closed construction not just extends the life expectancy of the switches but likewise reduces the frequency of upkeep and replacements, which is a crucial aspect for manufacturers and end-users alike.

Another advantage is their capability to endure extensive cycles of operation without deterioration in performance (Membrane Switch). This characteristic makes them particularly suitable for applications requiring constant usage, such as medical tools, commercial machinery, and customer electronic devices

Cost-Effectiveness

Additionally, membrane layer switches are normally produced making use of inexpensive products and processes. Their lightweight design not only reduces shipping costs but also enables less complicated combination into electronic devices. This can lead to additional cost savings in producing expenses, as structured setting up procedures decrease labor and time needs.

Additionally, the intrinsic simpleness of membrane layer button styles usually implies fewer components are required contrasted to traditional mechanical buttons. This decrease partially not just lowers production costs yet additionally minimizes factors of failure, enhancing integrity and performance.

In industries where budget restraints are important, such as customer electronic devices you could try here and industrial applications, the cost-effectiveness of membrane switches over comes to be particularly beneficial. Their ability to deliver consistent efficiency at a lower lifecycle expense placements them as a sensible selection for contemporary digital devices. Overall, buying membrane layer switches can bring about significant long-lasting savings for services and customers.

Modification Options

Customization alternatives for membrane layer buttons are extensive, enabling suppliers to customize these components to meet particular application requirements. One of the key advantages of membrane layer switches is their adaptability in layout. Manufacturers can select from a series of materials, consisting of polyester, polycarbonate, and acrylic, each offering distinct benefits in regards to longevity and aesthetic appeals.

Furthermore, membrane switches can be customized in different sizes and shapes to fit distinct device arrangements. This versatility encompasses the consolidation of various colors, graphics, and textures, making it possible for brand names to keep their aesthetic identity while improving individual experience (Membrane Switch). Furthermore, producers can integrate tactile responses features, such as printed keys or differing actuation pressures, to improve usability

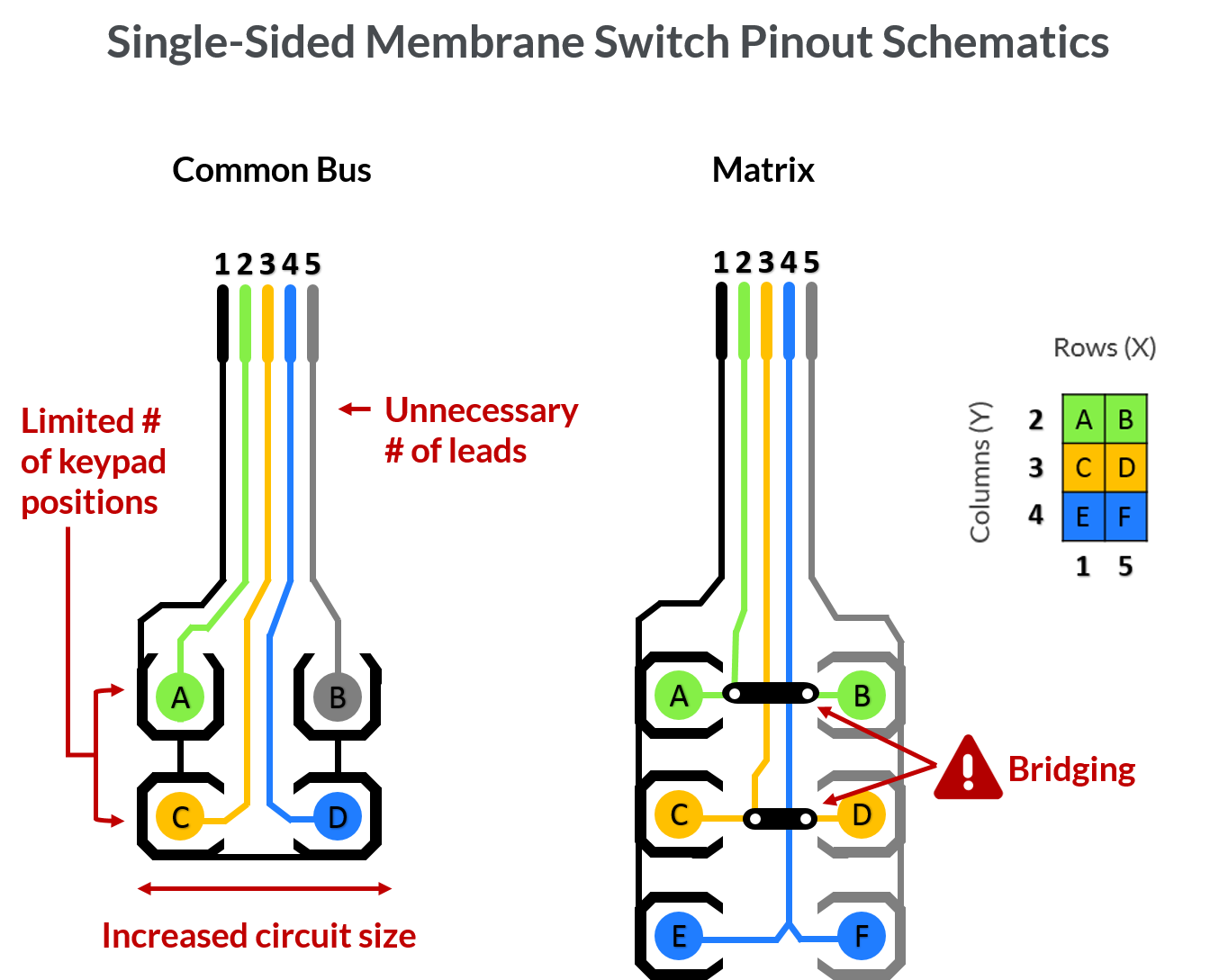

The printing innovation made use of for graphics and legends can additionally be customized, making certain high-resolution images and durable prints resistant to deterioration. Backlighting choices, such as LEDs, can be included to boost exposure in low-light environments. Lastly, personalized circuit designs permit particular capabilities, making it possible for manufacturers to develop switches that cater precisely to their product's demands. On the whole, these considerable customization options make membrane changes a compelling option for modern electronic tools.

Applications in Different Industries

Membrane layer buttons find substantial applications across a range of markets, showing their adaptability and functionality in various setups (Membrane Switch). In the healthcare market, they are commonly used in clinical tools, such as patient displays and diagnostic tools, where integrity and ease of cleaning are critical. Their sealed design helps stop contamination, making them suitable for settings that call for rigorous hygiene criteria

In the auto industry, membrane layer switches play a crucial duty in control panels and dashboards, providing an intuitive interface for motorists. The tactile feedback and personalized features enhance customer experience while making certain resilience against resonances and environmental variables.

Moreover, in commercial applications, membrane switches are used in equipment control systems, enabling direct and efficient customer communication. With their adaptability, membrane layer buttons use a robust solution that fulfills the diverse demands these days's technology-driven industries, proving necessary for both capability and aesthetic appeal.

Verdict

In final thought, membrane layer switches deal substantial advantages in modern-day digital equipment due to their design adaptability, sturdiness, and cost-effectiveness. The lightweight nature of membrane layer switches over further adds to lowered shipping costs and ease of combination.